Safe Industrialization

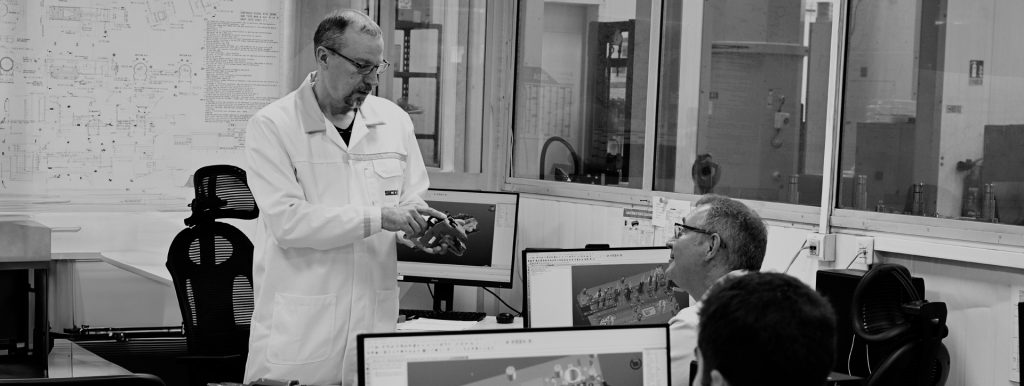

Manufacturing intelligence for greater efficiency

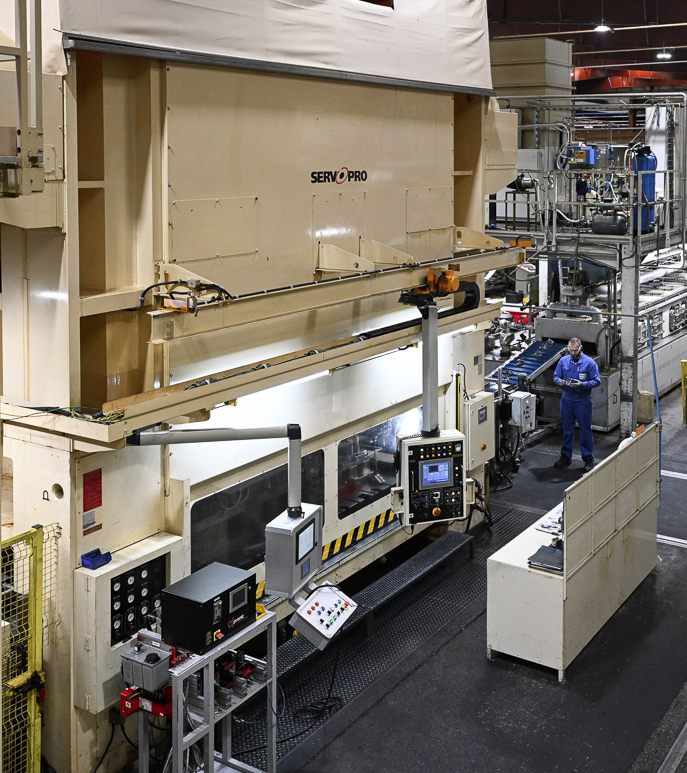

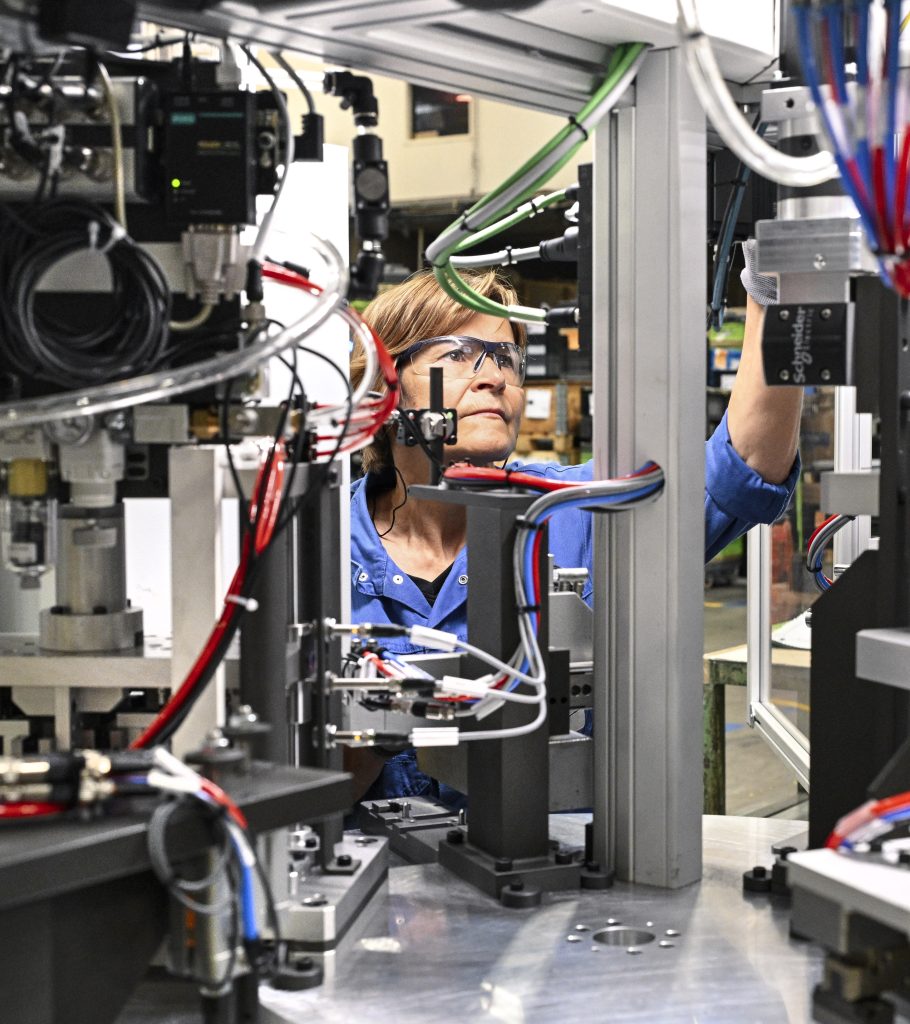

Our highly skilled team, composed of both men and women, utilizes a fleet of next-generation ultra-precise servo presses, enabling us to serve our global customers with remarkable efficiency. Our industrialized solutions span a wide range of expertise, from primary part stamping to mechanical and welding (CQI15) assemblies.

SCODER offers extensive material expertise, covering all types of steels with high mechanical properties (DP1000, 16MnCr5, S500 to S700), pre-coated materials, stainless steel, aluminum, copper and many more highly alloyed ferrous or non-ferrous metals.

Manufacturing efficiency

Servo press 800 tons Degreasing machine

Servo press 1200 tons

Welding robot

Multislide press

Key Figures about industrialization

Press

Coil width

Coil thickness

Tool length

Stamping tools

Welding

All our processes are monitored through a precise performance tracking and continuous improvement policy, ensuring we meet the highest quality standards and IATF certifications.

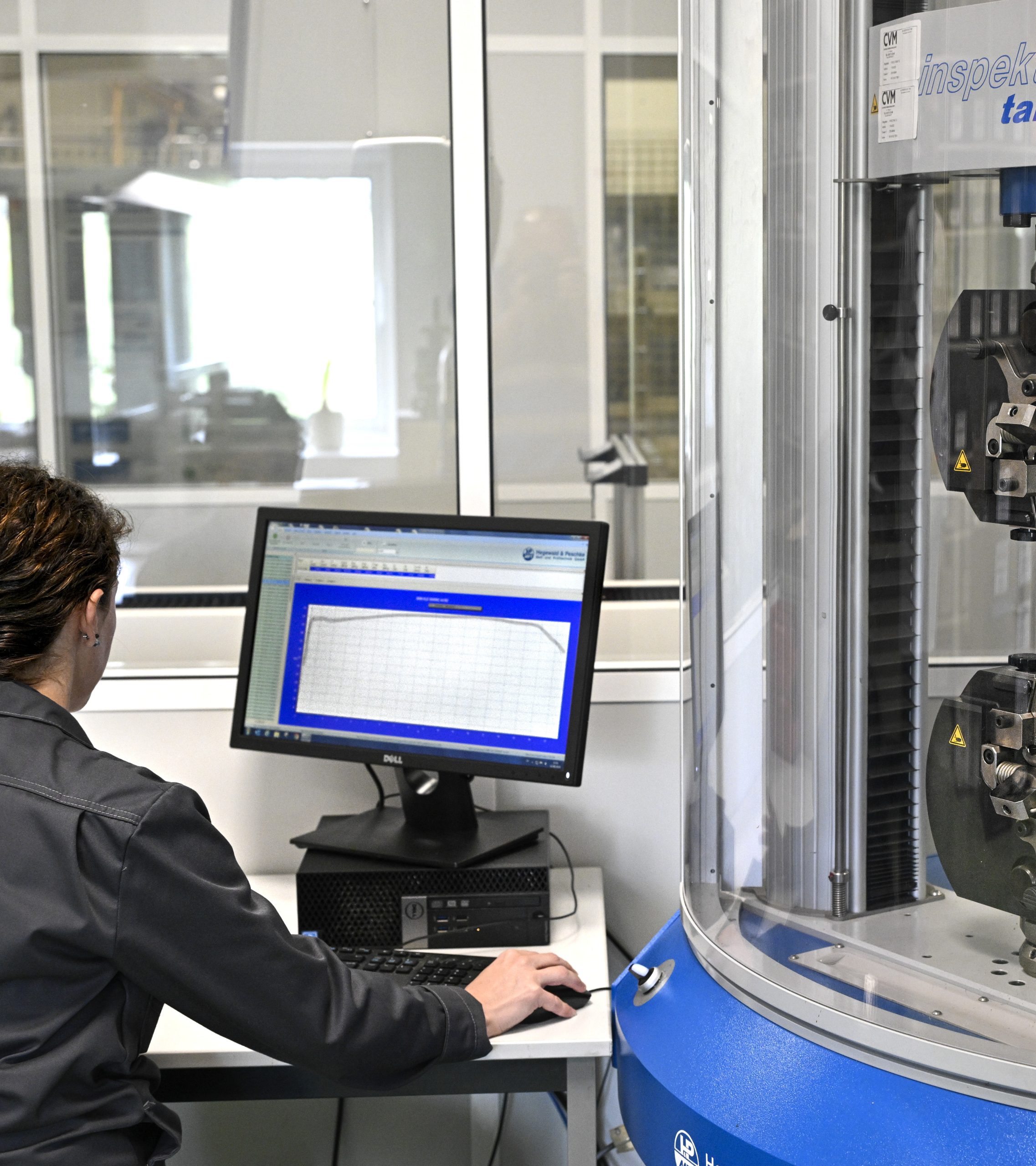

Our quality laboratory supports the daily operations of manufacturing control, enabling us to respond swiftly to meet the lead-time commitments of our customers’ new projects.

Based on our supplier policy, we ensure control of our incoming flows thanks to a raw materials testing laboratory.

Raw materials laboratory

Coordinate Measuring Machines

Frequency gages control

Automatic control

Safety criteria

Cross Functionnal Teams

In addition, we have developed a robust supply chain that has grown over the decades, ensuring reliable and capable delivery.

Located in a region renowned for its expertise in micro-technologies serving all types of industries, we work with reactive, highly qualified long-term partners for various applications, including:

- Deburring

- Technical surface treatments (CQI11/12)

- Heat treatment (CQI9)

- Cleanliness (ISO16232)

“Proud to contribute to a safer,

ecofriendly and sustainable mobility”